| Design | ||

| 1. Design Code | TIA/EIA-222-G/F | |

| Structure Steel | ||

| 2. Grade | Mild Steel | High Tensile Steel |

| GB/T 700:Q235B, Q235C,Q235D | GB/T1591:Q345B, Q345C,Q3455D | |

| ASTM A36 | ASTM A572 Gr50 | |

| EN10025: S235JR, S235J0,S235J2 | EN10025: S355JR, S355J0,S355J2 | |

| 3. Design Wind Speed | Up to 250 km/h | |

| 4. Allowable deflection | 0.5 ~1.0 degree @ operational speed | |

| 5. Tension strength (Mpa) | 360~510 | 470~630 |

| 6. Yield strength (t≤16mm) (Mpa) | 355 | 235 |

| 7. Elongation (%) | 20 | 24 |

| 8. Impact strength KV (J) | 27(20°C)---Q235B(S235JR) | 27(20°C)---Q345B(S355JR) |

| 27(0°C)---Q235C(S235J0) | 27(0°C)---Q345C(S355J0) | |

| 27(-20°C)---Q235D(S235J2) | 27(-20°C)---Q345D(S355J2) | |

| Bolts & Nuts | ||

| 9. Grade | Grade 4.8, 6.8, 8.8 | |

| 10. Standards for mechanical properties | ||

| 10.1 Bolts | ISO 898-1 | |

| 10.2 Nuts | ISO 898-2 | |

| 10.3 Washers | ISO 6507-1 | |

| 11. Standards for Dimensions | ||

| 11.1 Bolts | DIN7990, DIN931, DIN933 | |

| 11.2 Nuts | ISO4032, ISO4034 | |

| 11.3 Washers | DIN7989, DIN127B, ISO7091 | |

| Welding | ||

| 12. Method | CO2 Shielded Arc Welding & Submerged Arc Welding(SAW) | |

| 13. Standard | AWS D1.1 | |

| Marking | ||

| 14. Method of marking of the members | Hydraulic Press Stamping | |

| Galvanizing | ||

| 15. Galvanization standard of steel sections | ISO 1461 or ASTM A123 | |

| 16. Galvanization standard of bolts and nuts | ISO 1461 or ASTM A153 | |

| Test | ||

| 17. Factory test | Tensile test,Elements analysis, Sharpy test(impact test), Cold Bending, Preece test,Hammer test | |

| Capacity | ||

| 18. Maximum Production Capacity | 50,000 TON per annum | |

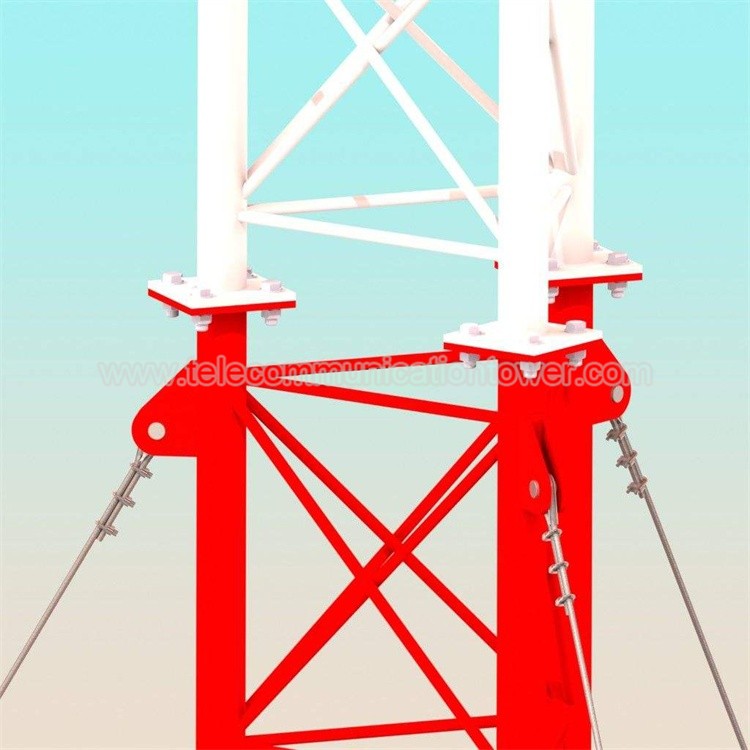

What is the general picture of the communication tower?

What are the foundation of the communication tower and guyed wire?

What is the connection between the guyed wire and the tower body of communication tower?

How to connect the guyed wire?